Image Source: i.ytimg.com

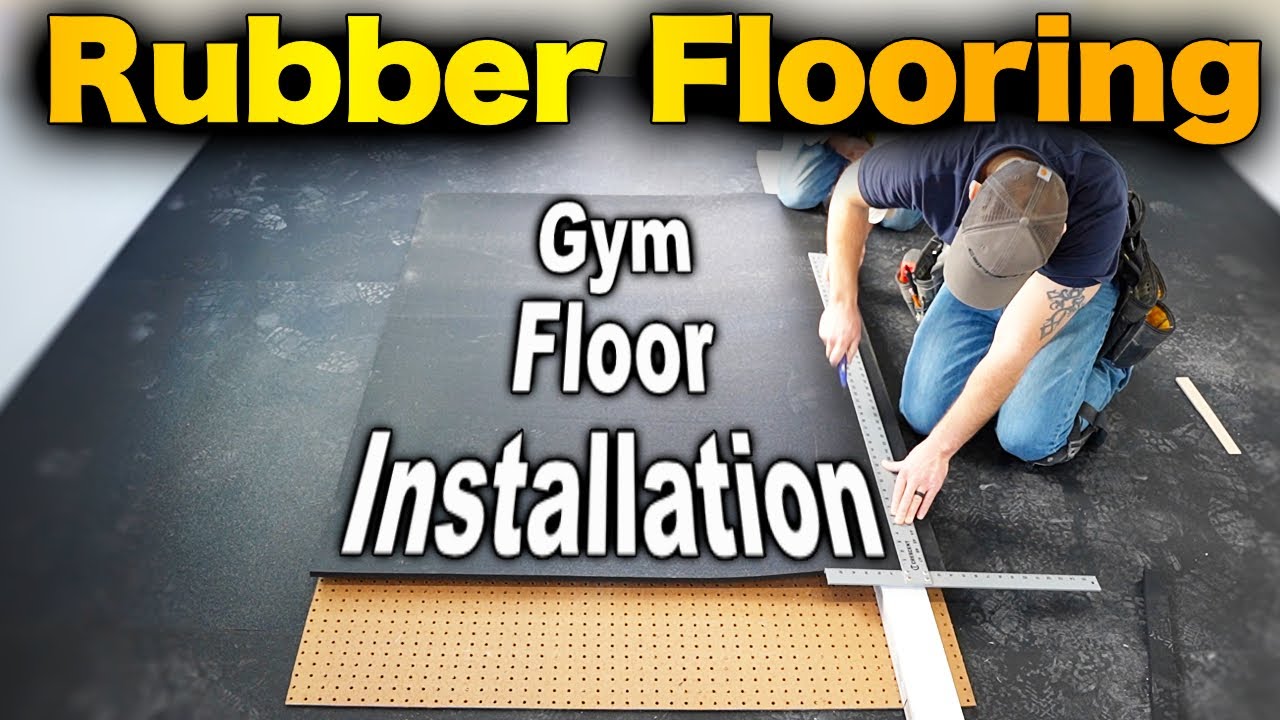

How To Install Gym Flooring: Get It Right the First Time

Putting in gym flooring yourself is a smart way to make your workout space better at home. It’s a job many people can do. You can handle the DIY gym flooring installation to make your room safe and ready for exercise. This guide tells you how to install gym flooring the right way. It covers everything from getting the floor ready to laying down the mats or tiles.

Picking Your Gym Floor Material

There are different types of flooring for home gyms. Your choice depends on what you plan to do in your space.

Different Floor Kinds

- Rubber Rolls: These cover large areas smoothly. They are good for heavy weights and cardio machines. Rubber gym floor mats often come in rolls.

- Rubber Tiles: These are easier to move and replace than rolls. Some lock together, while others need glue. You can find interlocking gym tiles made of rubber.

- Foam Tiles: These are soft and light. They are good for bodyweight exercises, yoga, and kids’ play areas. You can easily install foam gym floor tiles. They usually interlock.

- Vinyl: Some types of vinyl are tough enough for light home gym use. They look nice but might not be best for dropping heavy weights.

What Floor Works Best?

Think about how you will use the room.

* Heavy lifting needs thick, tough rubber. This protects your floor and your weights.

* Cardio machines need a stable surface. Rubber rolls or dense tiles work well.

* Bodyweight moves, yoga, or stretching are fine with softer foam or thinner rubber.

Getting Ready to Install

Good results start with good preparation. You need to get your space and your subfloor ready.

Clearing the Space

Take everything out of the room. You need a clear area to work. This lets you measure correctly and lay the floor easily.

Preparing the Base Floor

This is a very important step. The base floor is called the subfloor. Subfloor preparation for gym mats makes sure your new floor lies flat and stays in place.

* Clean: Sweep and vacuum the subfloor very well. Get rid of all dirt, dust, and small bits. Even small stones can cause bumps.

* Flat: The subfloor must be flat. Use a long level to check for high or low spots.

* High Spots: You might need to grind down concrete high spots.

* Low Spots: Fill small dips with a patching compound made for floors.

* Dry: Moisture is bad for gym flooring, especially rubber and wood. Check for dampness. You can tape a small piece of plastic sheeting to the floor. Leave it for a day. If you see water drops under the plastic, you have a moisture problem. Fix any leaks. You might need a moisture barrier if laying gym flooring on concrete floor.

* Stable: Make sure the subfloor is solid. Loose wood planks should be screwed down. Cracks in concrete might need filling.

Getting Tools and Materials

Gather everything you need before you start.

* Your chosen gym flooring (rolls, tiles, etc.)

* Measuring tape

* Utility knife or box cutter

* Extra blades (rubber dulls blades fast)

* Straight edge (like a metal ruler or a long level)

* Chalk line or pencil

* Gloves

* Safety glasses

* Knee pads (your knees will thank you)

* Floor adhesive (if needed)

* Trowel (for spreading adhesive)

* Roller (to press down glued floors)

* Cleaning supplies

Figuring Out the Best Layout

How you lay out the floor matters. It makes cutting easier and the final look better.

Measuring the Room

Measure the length and width of your room. Do this in a few spots. Rooms are not always perfect squares. Use the largest measurements. Multiply length by width to get the square feet (or square meters) needed. Add about 5-10% extra for cuts and waste.

Planning Your Starting Point

With rolls or large tiles, it’s often best to start along the longest straight wall. Or, you can start from the center of the room, especially with interlocking tiles.

* Center Start: Find the center point of the room. Snap chalk lines to make a cross in the middle. Lay the first tiles or piece here. This helps make cuts equal on all sides near the walls.

* Wall Start: Pick the straightest wall. This is often the wall you see most when you enter. Start laying your floor from this wall.

Dry Laying the Floor

If you are using tiles or mats that don’t need glue, lay them out first without sticking them down. This lets you see how they fit. You can adjust your start point to reduce waste or avoid tiny cuts at the end walls. This is key for how to lay interlocking gym tiles and foam tiles.

Gym Flooring Installation Steps

Let’s go through the steps to install your floor. The steps change a bit based on the type of floor you picked.

Step 1: Get the Subfloor Ready

We talked about cleaning, leveling, and drying the subfloor. This is the first real step on install day. Make sure it is completely ready. If you need a moisture barrier for gym flooring on concrete floor, put that down now.

Step 2: Plan Your Layout

Mark your starting point and guide lines. Use chalk lines or a pencil.

Step 3: Start Laying the Flooring

- For Interlocking Tiles (like rubber or foam):

- Start at your chosen point (wall or center).

- Connect the tiles by fitting the tabs together.

- Make sure the tiles are tight. Use a rubber mallet if needed, but be gentle not to damage the edges.

- Work your way across the room. Keep the edges lined up.

- For Rolls or Non-Interlocking Mats:

- Lay out the first full roll or mat along your guide line or starting wall.

- Let the material relax. Rubber rolls can be heavy and stiff. Let them sit for a few hours or overnight to flatten out.

- If using adhesive, apply it now (see Step 4).

- Carefully position the material.

- For Glued Floors:

- You might work in small sections if using glue. This is true for some rubber tiles and rolls.

- Apply glue to one section of the subfloor.

- Lay the flooring material onto the glue.

Step 4: Applying Adhesive (If Needed)

Not all gym floors need glue. Foam tiles almost never do. Many interlocking gym tiles stay in place with just their weight and friction. But thick rubber rolls or tiles might need glue.

- Picking the Glue: Use the best adhesive for gym flooring recommended by the flooring maker. This is often a specific type of flooring adhesive. Make sure it works with your subfloor (concrete, wood) and your flooring material (rubber, foam, vinyl).

- How to Apply: Use the right trowel size mentioned on the glue can. The trowel has notches. These notches leave the right amount of glue on the floor. Spread the glue evenly over a small area you can cover with flooring before the glue dries.

- Laying the Floor on Glue: Place the flooring onto the wet glue. Push it down firmly. Use a roller to make sure the whole piece touches the glue well.

Step 5: Cutting Around Edges and Obstacles

This is where you will be cutting rubber gym flooring or other materials.

- Measuring the Cut: Measure the space you need to fill. Mark the cut line on the back side of the flooring material.

- Making the Cut:

- Use a very sharp utility knife or box cutter. Change blades often! A dull blade makes bad cuts and is unsafe.

- Use a straight edge as a guide. Press down firmly on the straight edge.

- Score the material first with light pressure. Then make deeper cuts along the score line. It often takes several passes to cut through thick rubber.

- Cut on a safe surface, like a piece of scrap wood or cardboard. Do not cut directly on your subfloor or finished floor.

- Fitting: Test fit the cut piece. Trim more if needed.

Step 6: Filling the Room

Keep laying full pieces until you reach a wall or obstacle. Then cut and fit the pieces for the edges and around things like posts or doorways.

- Work across the room methodically. With tiles, work in rows or sections. With rolls, lay one roll, cut it to length, then lay the next.

- Pay attention to seams between pieces. They should be tight.

Step 7: Finishing the Edges

Once the main floor is down, you might need to finish the edges. This is gym floor trim installation.

- No-Glue Floors: Interlocking tiles might leave exposed edges. You can buy edge pieces that connect to the border tiles. These give a clean look and a slight slope.

- Glued Floors/Rolls: The raw edge might be fine, or you might use a metal or rubber trim strip along the base of the wall. This is like baseboard trim for regular floors. It covers the gap and gives a finished look.

- Cutting Trim: Measure and cut trim pieces using a saw or utility knife, depending on the trim material. Attach them with adhesive or small nails/screws.

Step 8: Clean Up

Remove scraps and trash. Clean any glue spills while they are still wet. Sweep or vacuum the new floor.

Taking a Closer Look at Specific Flooring Types

The gym flooring installation steps are similar, but some details change based on the material.

Installing Rubber Rolls

These are heavy and can be hard to handle alone.

* Roll out the rubber. Let it rest to flatten.

* Trim one edge perfectly straight if needed. This will be your starting edge against the wall or guide line.

* If gluing, apply glue to the subfloor for the first section.

* Carefully place the rubber onto the glue, keeping the straight edge aligned. Use a roller to press it down.

* Roll out the next piece next to the first. Butt the seams tightly together. Avoid leaving gaps.

* Repeat the gluing, placing, and rolling for each section or roll.

* Cut ends and sides to fit using the score-and-cut method with a sharp knife.

Installing Rubber Tiles

Whether interlocking or straight-edge, rubber tiles are more manageable.

* Interlocking: Start with a tile in your chosen spot. Add the next tile by lining up the edges and pressing or tapping them together. Make sure the pattern (if any) lines up. Work outwards or in rows.

* Straight-Edge: These often need adhesive. Apply glue to the subfloor. Lay the tiles in the glue. Press firmly. Use a roller if needed. Make sure edges are tight.

Installing Foam Gym Floor Tiles

This is often the easiest type of DIY gym flooring installation.

* Foam tiles are light and cut easily.

* They almost always interlock.

* Start in a corner or along a wall. Lay the first tile. Add the next by linking the edges.

* They fit together like puzzle pieces.

* Use a utility knife to cut pieces for the edges. They cut much easier than rubber.

Cutting Rubber Flooring Right

Cutting rubber gym flooring is probably the hardest part of a DIY install, especially with thick material.

- Tool: A sharp utility knife is key. Buy a pack of extra blades. You will use them.

- Method: Always use a straight edge. Metal rulers are good because the knife won’t cut into them. Place the straight edge on the rubber where you want to cut.

- Process:

- Hold the straight edge down firmly.

- Using moderate pressure, run the knife along the guide. This scores the rubber.

- Make several more passes along the same line. Each time, press a little harder. The blade will go deeper.

- Do not try to cut through thick rubber in one go. You need to cut it layer by layer.

- For thick material, you might cut halfway through, then bend the rubber slightly along the cut line to open it up, and continue cutting.

- Curves: For curves around posts, make a template out of paper first. Trace the template onto the rubber. Cut the curve using the utility knife freehand, or make many small, straight cuts.

- Safety: Always cut away from your body. Wear gloves and safety glasses. Keep fingers clear of the blade.

When to Use Adhesive

Deciding on the best adhesive for gym flooring depends on the floor type and use.

- Heavy Use: If you plan to drop heavy weights, glue down thick rubber rolls or tiles. This stops them from shifting.

- Large Areas: For very large rooms, gluing helps keep everything stable over time.

- Permanent Install: If you know this is a long-term floor, adhesive makes it stay put.

- Loose Lay: Foam tiles and many interlocking rubber tiles can be “loose laid.” Their weight keeps them down. This is good if you might move later or want to use the floor in a different room.

- Hybrid: You can loose lay most of the floor but glue down the edges and seams in high-traffic areas.

Talk to the company where you buy the flooring. They can suggest the right glue for their product and your subfloor. Water-based adhesives are common but need the subfloor to be dry and non-porous (like concrete). Polyurethane adhesives are strong and work on many surfaces.

Gym Floor Trim: The Final Touch

Gym floor trim installation makes the job look finished and tidy. It covers the gap between the flooring and the wall.

- Purpose: Trim hides slight imperfections in cutting along the wall. It also stops the edges of the gym floor from lifting up over time.

- Types:

- Edge Pieces: For interlocking tiles, specially made edge pieces snap onto the outside border tiles.

- Baseboard/Cove Trim: Rubber or vinyl trim can be glued or tacked along the wall base. It looks like standard home trim but is flexible.

- Transition Strips: Use these in doorways where the gym floor meets a different type of floor.

- Installation:

- Measure and cut trim pieces to fit each wall or edge. Use a utility knife for rubber/vinyl trim, or a saw for stiffer trim.

- Attach edge pieces by clicking them onto the tiles.

- Attach baseboard trim with recommended adhesive or small finish nails.

- Attach transition strips using screws, nails, or adhesive, based on the product.

Tips for Getting It Right the First Time

- Measure Twice, Cut Once: Standard advice, but super important with expensive flooring.

- Use a Fresh Blade: This cannot be stressed enough for cutting rubber gym flooring. A new blade makes cleaner cuts with less effort and is safer.

- Allow for Expansion: Some materials, especially foam, can expand a little with heat. Leave a small gap (maybe 1/4 inch or less) around the edges against the wall. Trim will cover this. Rubber is less likely to expand much.

- Check for Square: As you lay tiles or rolls, step back often to make sure your rows are straight and square. It’s easier to fix a small drift early on.

- Work With a Friend: Laying heavy rubber rolls is much easier with two people.

Common Mistakes to Avoid

- Poor Subfloor Prep: Laying gym flooring over a dirty, uneven, or wet subfloor will cause problems later. The floor might buckle, lift, or mold.

- Using a Dull Knife: This leads to jagged cuts, wasted material, and frustration.

- Wrong Adhesive: Using the wrong glue can mean the floor doesn’t stick or damages the subfloor/flooring.

- Not Letting Rolls Acclimate: Rubber rolls can shrink or expand slightly based on room temperature. Let them sit in the room for 24 hours before cutting and laying.

- Leaving Big Gaps: Measure carefully so edge pieces fit well. Big gaps look bad and can be a trip hazard.

- Ignoring Safety: Cutting tools are sharp. Heavy rolls are heavy. Protect yourself.

Keeping Your Gym Floor Clean

Once your DIY gym flooring installation is done, keep it clean.

* Sweep or vacuum often to remove dirt and grit. This stops the floor from getting scratched.

* Wipe spills right away.

* Clean with a mild soap and water mix. Do not use harsh chemicals, as they can harm rubber or foam.

* Do not use too much water, especially on seams or loose-lay floors.

Frequently Asked Questions (FAQ)

Can I install gym flooring over carpet?

No. Carpet is too soft and not stable. Gym flooring needs a hard, flat base like concrete or wood. You must remove carpet and padding first.

How thick should gym flooring be?

It depends on use.

* 3/8 inch (8mm) is common for general fitness and moderate weights.

* 1/2 inch (10-12mm) is better for heavier weights and dropping dumbbells.

* Thicker options (1 inch or more) are for serious weightlifting areas where heavy bars are dropped often.

* Foam tiles are usually 1/2 inch or thicker but are much softer.

Is it okay to put heavy machines on interlocking tiles?

Yes, but put something solid like a piece of plywood under the machine legs. This spreads the weight and stops the machine from making dents in the tiles.

How do I get rid of the smell of new rubber flooring?

New rubber can have a strong smell. This smell goes away over time. Make sure the room has good airflow. Open windows if possible. Cleaning the floor with a mild soap and water solution can sometimes help speed up the process.

What is the cost of DIY gym flooring installation?

The cost varies a lot based on the material chosen and the size of the area. Foam tiles are cheapest, rubber tiles cost more, and thick rubber rolls can be the most expensive per square foot. Doing it yourself saves money on labor costs.

Can I lay rubber flooring directly on concrete?

Yes, gym flooring on concrete floor is very common. You must make sure the concrete is clean, flat, dry, and free of moisture issues before installing. A moisture barrier might be needed.

How long does gym flooring last?

Good quality rubber flooring can last 10-15 years or even longer with proper care. Foam tiles may need replacing sooner if they see heavy use, perhaps 5-10 years.

By following these gym flooring installation steps, taking your time, and preparing well, you can successfully put in your own gym floor. Enjoy your new, safer workout space!